The extrusion process

- Billets are heated up 480° and insert in the press container.

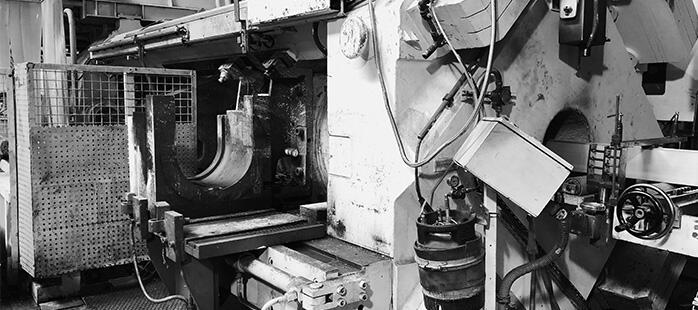

- The extrusion press exerts a high pressure on this Billets which is pressured through a die. Thus the profile is formed. Profils Systemes uses more than 3 000 different dies !

- After the press process, profiles are immediately cooled down to a 100° temperature.

- They are tractionned and stretched to finalize their shape.

- They are cut according to market commercial size.